Hot rolled section steel production line

Published Time:

2018-04-20 18:19

Source:

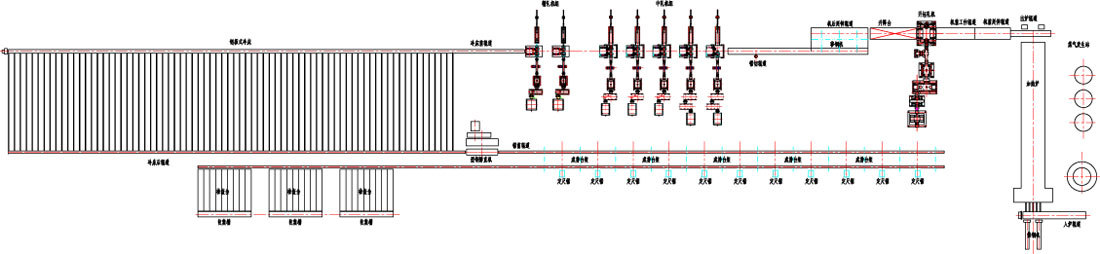

The products are small or medium size angle steel, channel steel, steel I beam, flap steel, square steel, guide rail, hub steel, rockbolt etc., billet size are130×130~160×160×(3000-12000)mm.

The products are small or medium size angle steel, channel steel, steel I beam, flap steel, square steel, guide rail, hub steel, rockbolt etc., billet size are130×130~160×160×(3000-12000)mm. The roll speed is about 5-15m/s and the maximum annual output are 20,000~700,000 tons with the single line rolling.

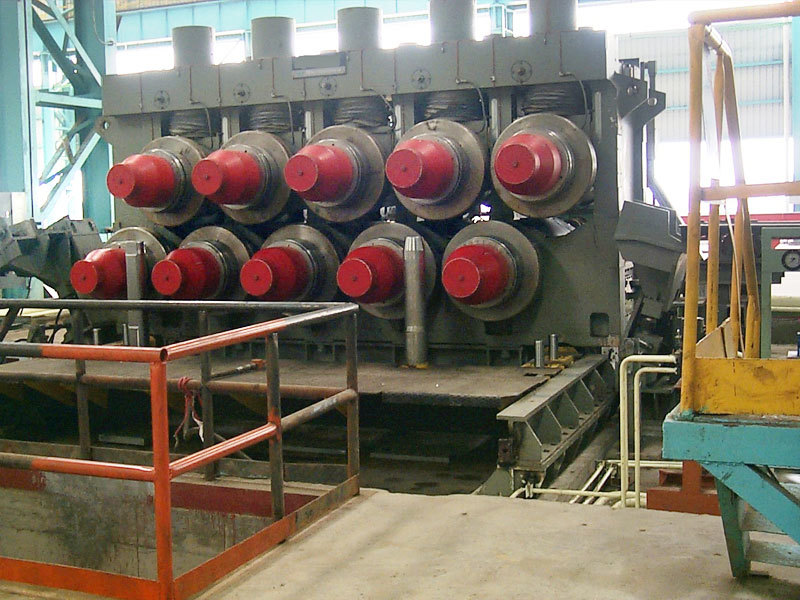

The main equipment of the section steel production line are horizontal or vertical housing mill (or H/V housing less stands)of 610-350 size, pusher, discharger, start/stop type crop plying shear, dividing flying shear(or hot saw), apron board walking rake cooling bed, straightening machine, row up rack, cold dividing shear (or cold dividing saw), finishing machine, tying & collection machine etc.

-

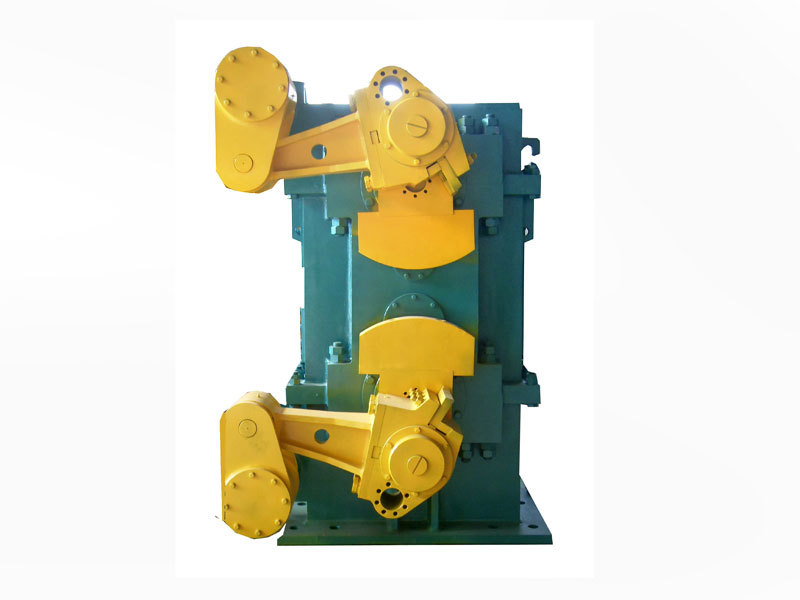

Three high roughing mill -

Closed housing stands mill -

Hot saw -

Dividing shear -

Cooling bed -

Straightening machine

Related News

Streamlining Steel Manufacturing: The Ultimate Rolling Mill Production Line

Discover how to optimize your steel manufacturing process with the ultimate rolling mill production line. This comprehensive guide will provide you with valuable insights and strategies to streamline

Key Facts About Rolling Mill Production Line for Steel Plants

Discover the essential information about rolling mill production lines for steel plants in the manufacturing and processing machinery industry. Gain valuable insights into this aspect of metal process

Discover how incorporating an advanced rolling mill production line can significantly enhance the efficiency of steel plants, revolutionizing the manufacturing process. Learn about the latest technolo