Hot strip production line

Published Time:

2018-04-20 18:19

Source:

It produces strip steel and sheet steel, 125-450mm in width, 1.5-20mm in thickness. The production capacity is 200,000-800,000 tons per year.

It produces strip steel and sheet steel, 125-450mm in width, 1.5-20mm in thickness. The production capacity is 200,000-800,000 tons per year.

The main equipment of the strip production line includes 650 two-roller reversing mills, 550 two-roller mills, four-roller strip mills and vertical mills, horizontal mandrel less coiler, vertical coiler, pusher, discharger, cutting shear, transportation and packing machine.

-

Strip mills -

Hot strip on transport line -

Regulating cabinet -

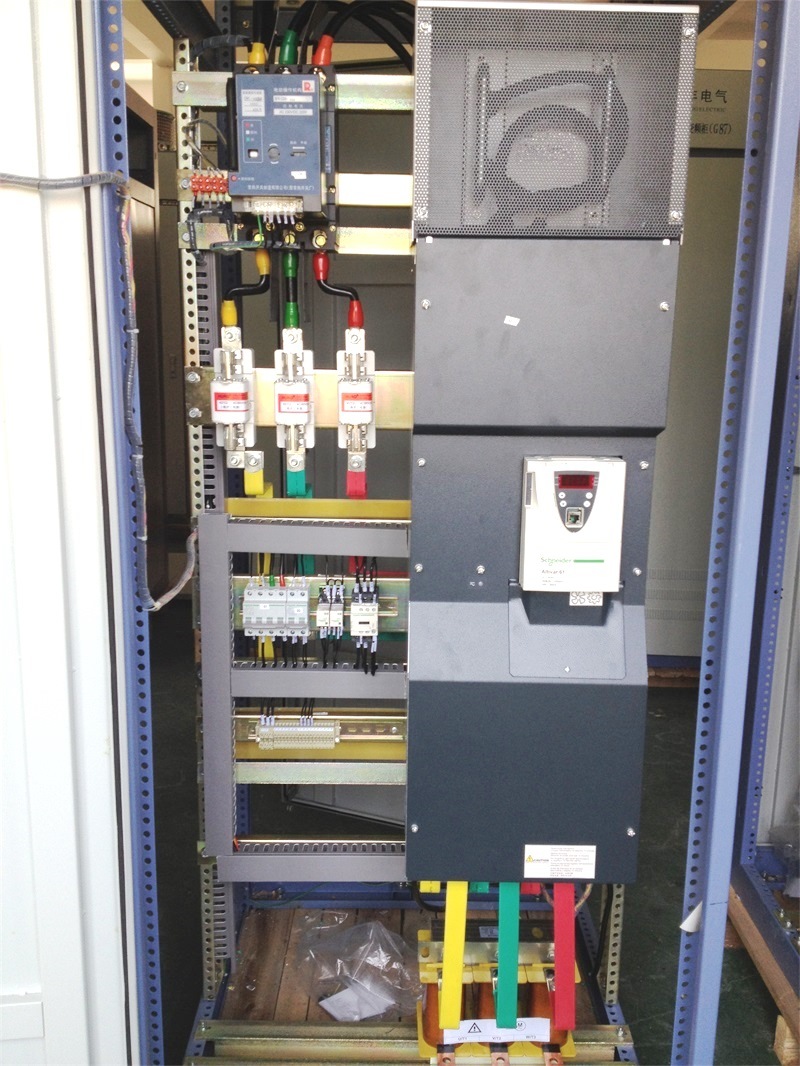

Control cabinet

Control cabinet

Electrical control equipment

Jinquan group electronic factory is a high and new technology industry as the pillar, is vigorous in the development of new enterprises. Mainly engaged in AC and DC electric drive system, automatic control system and device research, design, development and production, not only can take electric engineering contracting project independently, but also can design and provide a modern complete drive equipment and advanced control system for the user, especially in dive and automation engineering of metallurgy industry, wire, bar and strip. With the annual output of more than 300 sets various control devices (cabinet), and with the excellent technology and reliable quality has won a large number of users, has gradually become the automation industry well-known enterprise.

The characteristics of drive and automation system we provide:

DC drive control system adopts Siemens 6RA70 as the core control part, and high-power thyristors that produced by imported production line as the core power part, combine with the two technology is composed of motor speed regulating device, this device can reach the international advanced level, and the price is not expensive, it can realize the optimum cost performance.

The AC frequency conversion motor drive adopts Siemens, ABB, Schneider and other international brands of inverter as a core component, with characteristics of the advanced control concept, high control accuracy, energy saving.

Automation system uses the PROFIBUS-DP and industrial Ethernet which are widely used in domestic and foreign. Two layers of distributed communication network system, are used to control and process management and monitoring.Jinquan group electronic factory is a high and new technology industry as the pillar, is vigorous in the development of new enterprises. Mainly engaged in AC and DC electric drive system, automatic control system and device research, design, development and production, not only can take electric engineering contracting project independently, but also can design and provide a modern complete drive equipment and advanced control system for the user, especially in dive and automation engineering of metallurgy industry, wire, bar and strip. With the annual output of more than 300 sets various control devices (cabinet), and with the excellent technology and reliable quality has won a large number of users, has gradually become the automation industry well-known enterprise.

The characteristics of drive and automation system we provide:

-

DC drive control system -

AC frequency conversion control cabinet -

AC frequency conversion control cabinet -

Automatic control system

Related News

Streamlining Steel Manufacturing: The Ultimate Rolling Mill Production Line

Discover how to optimize your steel manufacturing process with the ultimate rolling mill production line. This comprehensive guide will provide you with valuable insights and strategies to streamline

Key Facts About Rolling Mill Production Line for Steel Plants

Discover the essential information about rolling mill production lines for steel plants in the manufacturing and processing machinery industry. Gain valuable insights into this aspect of metal process

Discover how incorporating an advanced rolling mill production line can significantly enhance the efficiency of steel plants, revolutionizing the manufacturing process. Learn about the latest technolo