How to maintain hot rolling mill machines

Published Time:

2021-05-07 15:49

Source:

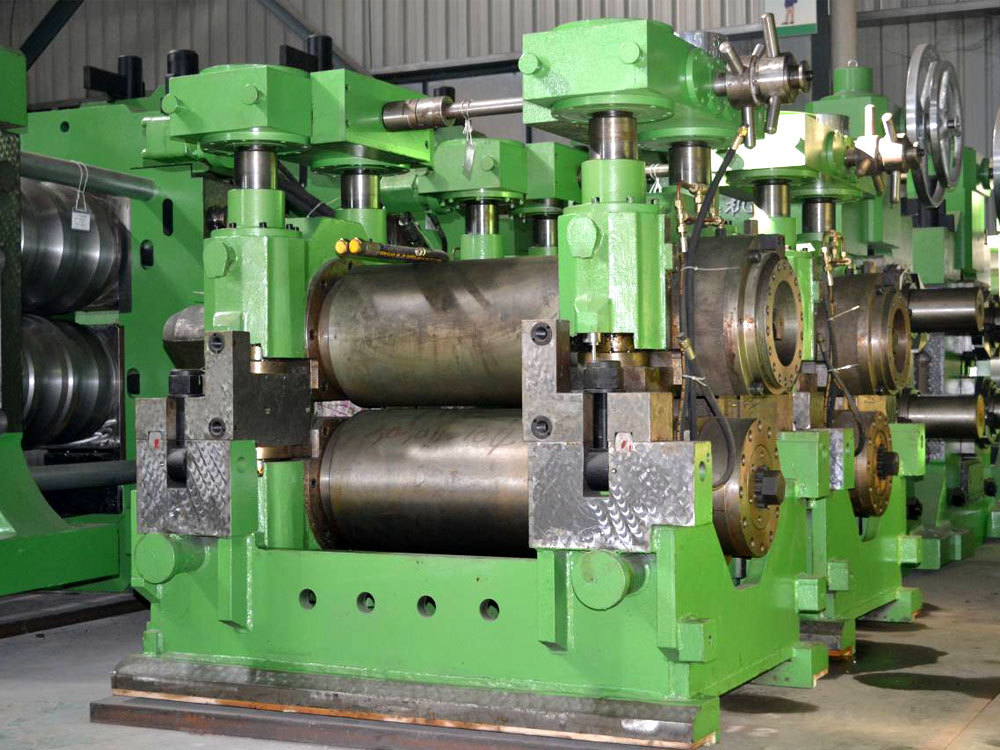

Hot rolling mill machines are commonly used steel rolling machines. Daily maintenance is particularly important. The rolling mill is checked every day for oil, water, gas leakage and overheating of the machine parts; to reduce the loss caused by illegal operation of equipment or untimely maintenance. When moving the rubber roller, the chain, rope and the end of the roller surface are required. If the maintenance is not in place, the service life will be greatly reduced. So how to maintain hot rolling mill machines, and how to perform daily maintenance of hot rolling mill machines, and how to do it?

There are several steps in the maintenance procedures of hot rolling mill machines. The automatic thickness control system on the rolling mill strictly follows the mill operation and processing procedures and operating methods. The gearbox is maintained at least once a season. The gearbox must be cleaned when the rolls are fed to the limited position. Pay attention to the safe operation of steel rolling equipment. When operating hot rolling mill machines, be careful that your hands are pressed by the steel plate and rolled in with the steel feed. When using a crane to lift hot rolling mill machines for inspection, be careful not to collide with the machine.

Follow the instructions of the person in charge of the rolling mill production line. According to the different process requirements of the rolling water and the padding treatment liquid, there is no signal. The contact parts of the rollers are filled with elastic materials (such as multi-layer fabrics, waste yarn groups, thick wood boards, etc.). In the process of rolling steel, the roller and raceway are in line contact or repaired offline contact. The radial load capacity is large, which is suitable for bearing heavy load and impact load. If irregular noise is found, such as the roll after the steel bar is interrupted, the roller cannot be Abnormal phenomena such as impact and impact due to sudden load release should be shut down immediately for inspection, and maintenance can be carried out after the steel rolling production line is completely stopped. After the main drive of the motor is stopped, the upper and lower rolls can be raised and lowered. When cleaning, the upper and lower rolls can be raised and lowered first. When stopping, unscrew the oil drain plug at the side of the gearbox, turn over the roll to reset and the upper roll to tilt.

customized,hot,rolling,mill,machines,Steel,Rolling,Mill,Machines,Manufacturers,china

Related News

Streamlining Steel Manufacturing: The Ultimate Rolling Mill Production Line

Key Facts About Rolling Mill Production Line for Steel Plants